Energy Solutions

Energy Solutions>Project Highlights

Project Highlights

EMS Implementation at BMT Headquarters

최고관리자

2025-06-13 17:43

Read 482

year

2024

Customer

BMT Co., Ltd. Headquarters

details

Installation of Smart-Eye devices and panel PCs, real-time power monitoring, solar power tracking, integrated gas/water/electricity management, system air conditioner control, and EV charging monitoring

[Testbed Story] Cutting-Edge EMS Under Real-World Testing at BMT Headquarters!

BMT’s EMS has proven itself across various sites — and now it’s being deployed and tested at the company’s very own headquarters as the latest-generation testbed. Located in Gijang, Busan, the BMT HQ encompasses a manufacturing plant, dormitory, and cafeteria, requiring extensive energy management across diverse facilities. Real-world data is being used to further enhance EMS functionalities and verify its effectiveness in energy reduction.

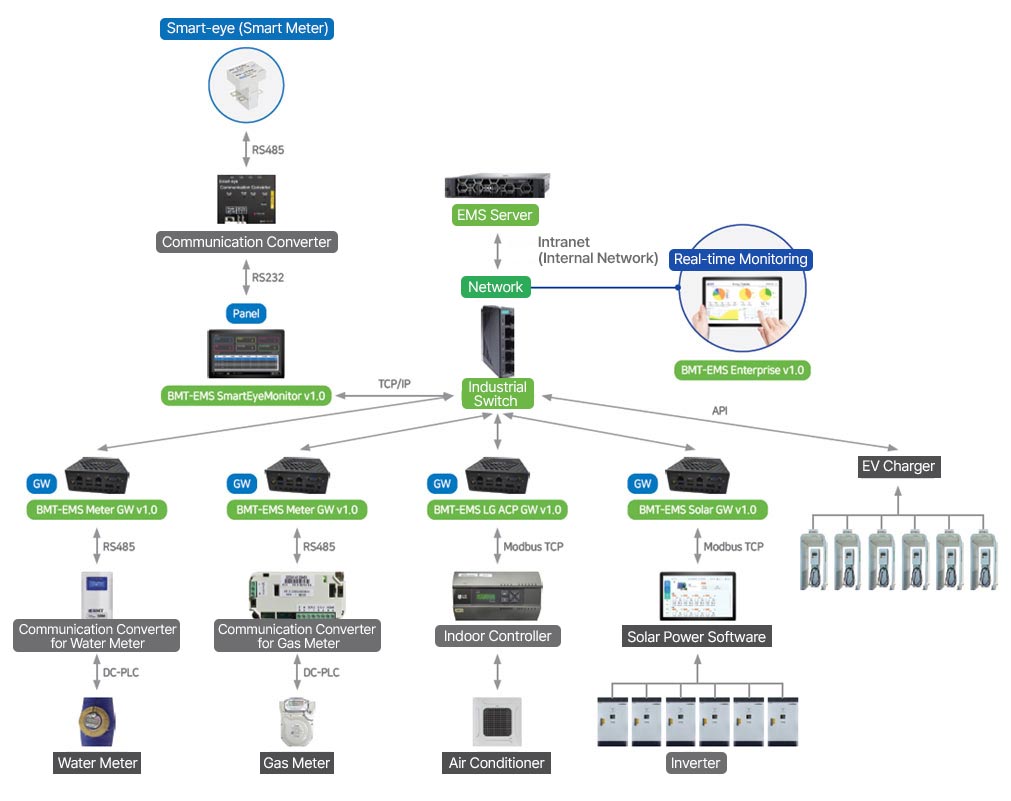

[BMT HQ EMS Implementation Diagram]

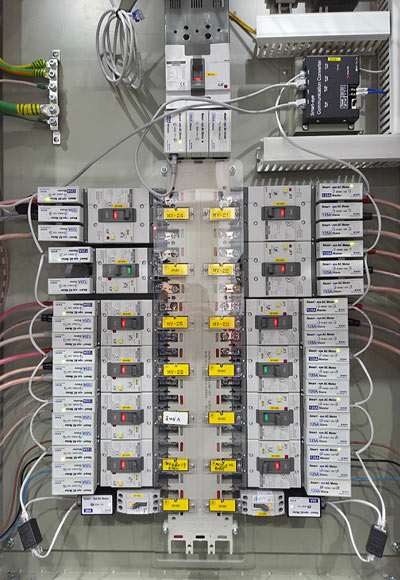

1. SmartEye & Panel PCs – At the Heart of Power Monitoring

SmartEye devices are installed across distribution panels at BMT HQ, collecting precise power usage data and displaying it in real time via panel PCs. The system provides complete visibility — from main power lines to individual loads — and sends data to the server every 5 minutes for analysis.

Production Site Distribution Panel

Office Building Distribution Panel

Inside Panel – with Smart-eye Installed

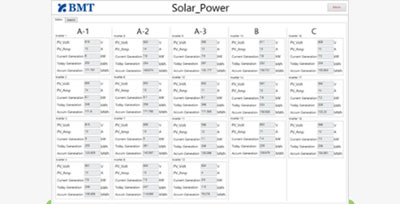

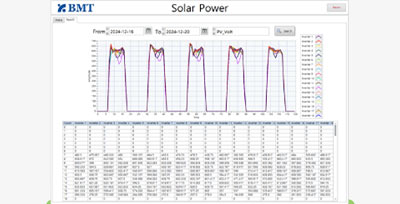

2. Solar Power Integration – The Silent Contributor

Solar panels are installed on the rooftop of the BMT headquarters and the factory building. While output can vary depending on weather conditions, they currently generate about 15–30% of the factory’s energy consumption. Through the EMS, solar generation status can be monitored in real time — enabling not only efficiency tracking but also immediate detection of any abnormalities.

Solar panel

Screen (Solar Power Status)

Screen (Solar Power Search)

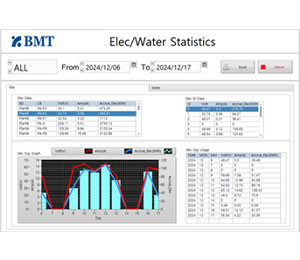

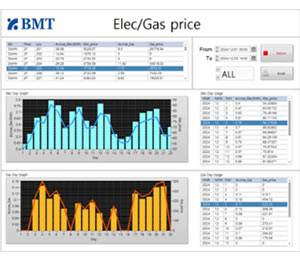

3. Dormitory Utility Management – Electricity, Gas, and Water

BMT Smartly Manages Even the Dormitories!

- Each room’s electricity usage is measured using Smart-eye devices, and utility charges are automatically calculated based on KEPCO’s seasonal and time-based rate structure.

- Gas consumption is monitored via smart gas meters with communication functions, and the data is directly used for utility billing.

- Water meters installed on the rooftop provide real-time monitoring of water usage by building.

As a result, utility billing has become much more accurate, and energy waste is significantly reduced.

Water Meter Communication Converter

Gas Meter Communication Converter

Data View Screen

Billing Calculation Screen

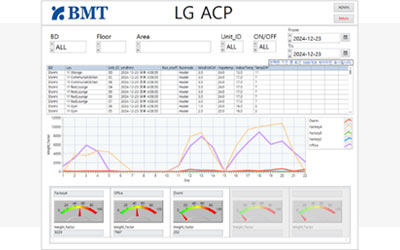

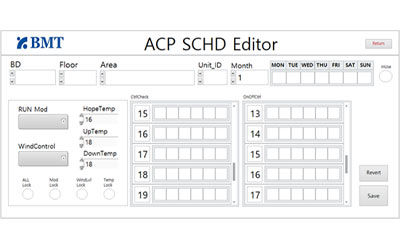

4. System Air Conditioning – Smarter, More Efficient Control

The system air conditioners installed in the factory and office buildings are also integrated into the EMS. They can be automatically scheduled and controlled 24/7 in 10-minute intervals — by building, floor, or individual unit. This allows for fine-tuned energy usage patterns and minimizes unnecessary waste. Even during the summer, cooling stays smart and efficient!

Air Conditioner Control Panel

Data Monitoring Screen

Schedule Control Screen

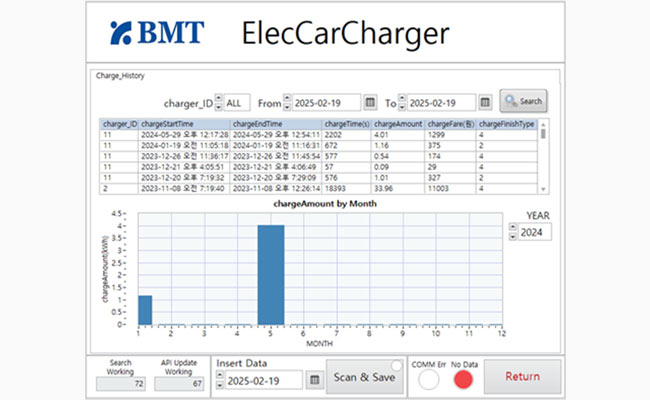

5. EV Charging – Real-Time Status at a Glance

EV chargers are installed in the parking lot at BMT headquarters, and their charging status can be monitored in real time through the EMS. Charging history is also easily accessible, making overall operation and management much more efficient.

EV charger

ElecCarCharger Screen

6. Edge Computing – Smarter Data Processing

The gateway devices are more than just relays — they’re equipped with edge computing capabilities. This allows data to be pre-processed directly at the site, enabling immediate execution of automated functions such as air conditioner control. As a result, server load is reduced, and the entire system becomes faster and more stable.

Gateway

7. Remote Integration Without Boundaries

One unique feature of the system is that EMS monitoring is carried out at the BMT headquarters in Busan, while the database server is located in Seoul. Through the company’s intranet, data is stored and processed in real time, allowing for seamless two-way access anytime. Despite the geographic distance, the system remains fully integrated and highly responsive.

Server Room

Control Room

BMT headquarters has now become a testbed for the latest EMS technologies, where real-world experimentation and validation are actively taking place. We will continue to take steps forward toward smarter and more efficient energy management.