Electric Products

Compact Switchboards

02.

Compact Switchboards

Safety-enhanced and compact-structured switchboard with MCBS (Molded Case Busbar System),

BMT's own patented technology.

Features

Compact structure to save space

- Reduces volume and busbar by more than 40% and 10% respectively, compared to conventional switchboards.

- The structure of separating each phase (R/S/T/N) reduces the restriction of clearance/creepage distance.

- Maximizes the practical space use of the electrical room and reduces construction costs.

- Height of electrical room : about 700mm ↓(For TR Capacity of up to 500kVA)

- Height of electrical room : about 500mm ↓(For TR Capacity of up to 750kVA)

- Height of electrical room : about 400mm ↓(For TR Capacity of up to 1000kVA)

Convenient operability and expandability

- Modulization enables disconnection of individual module and partial replacement/repair.

- Simple extension and convenient connection with existing busbar lindes.

- Allows for a busbar system that can be installed without additional support insulators, and enables easy installation and maintenance.

Innovative safety and excellent durability

- A flame retardant material is applied to MCBS (PA66 GF30% Flame Retardant Reinforced) in order to eliminate the risk of accidents caused by electric shock or short circuit and to prevent fires from spreading.

- By maintaining the MCBS’s dielectric strength completely (up to 20 kV) with a closed structure separating each busbar, the systems and workers are safe from the risk of short circuit/ground fault/electric shock caused by incomplete power supply, moisture, dust, etc.

- Anti-loosening lock bolts are applied to busbar to protect it from vibration due to resonance, etc.

- An earthquake-resistant design (zone 4 level or seismic intensity 7) is adopted for the enclosure to enhance safety.

Reliable Trusted Products

Verified with Patents (Korea) and certificates, such as KERI Type Approval, K-mark, Excellent Performance Certification (by Korean MSS), and Excellent Product Certification (by Korean PPS)

Specifications and Composition

Specifications

- Rated Voltage 24/25.5kV/7.2kV/3.6kV

- Rated Current ~2000A, or other customer spec

- Rated Frequency 60/50 Hz

- Rated Short Time Current:1sec Max. 25 kA

- Rated Operating Voltage AC220V,110V, or other customer spec

- Degree of Protection IP4X, or other customer spec

- Dimension(mm) (W)800~1200, (D)2000~2500, (H)1800~2100

- Certificate KERI Type Test Report (by KERI, Korea), K-Mark, Excellent Performance Certification (by Korean MSS), Excellent Product (by Korean PPS)

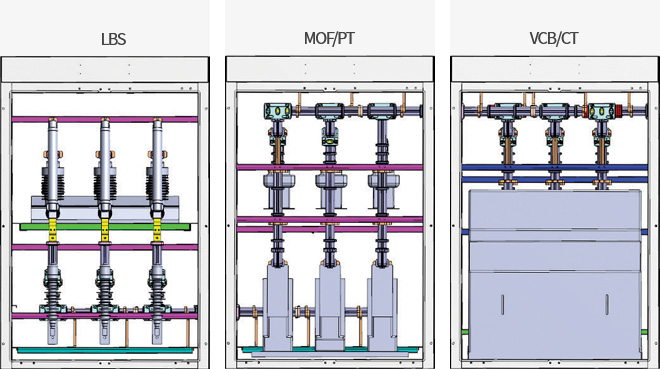

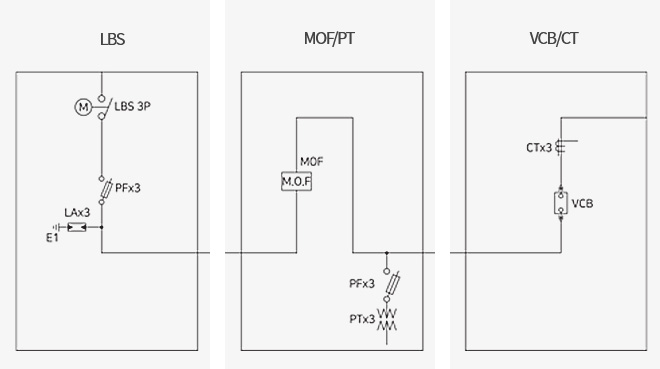

Panel Composition

-

Front View (Layout of Internal Devices)

-

Block Diagram

Specifications of Major Internal Devices

| Panel | Device | Rated |

|---|---|---|

| HV-1 | LBS | 24kV 630A |

| LA | 18kV 2.5kA | |

| HV-2 | MOF | 24kV 13200/110V/5A |

| PT | 24kV 13200/110V/200VA | |

| PF | 24kV 200A 40kA | |

| HV-3 | VCB | 24kV 630A 25kA |

| CT | 24kV/5A 40VA | |

| SA | 18kV 5kA |

MCBS(Molded Case Busbar System)

MCBS is the world's first modular assembly busbar system made with BMT's own patented technology.

- The BMT compact switchboard with MCBS dramatically reduces the spatial constraints of power receiving facilities and electrical rooms in factories, buildings, etc.

- The closed structure made of the flame-retardant material protects against electric shock and short circuits, thus preventing fire and safety accidents

| Material | PA66 (Polyamide 66) + GF30% | |

|---|---|---|

| Physical Properties of Nylon 66 | Specific gravity | 1.14 |

| Tensile strength | 840 (kg/cm²) | |

| Elongation | 60% | |

| Bending strength | 28800 (kg/cm²) | |

| Impulse strength | 5.4 (kg ·cm²/cm) | |

| Continuous operating temperature | 115℃ or higher | |

| Heat deflection temperature | 130℃ or higher | |